Planing patterns and sleuthing origins

by David Shields. Average Reading Time: about 2 minutes.

Identifying the manufacturers and clarifying, as precisely as possible, the origin of the designs of the types in the Rob Roy Kelly American Wood Type Collection has been an important component of my ongoing research into nineteenth century typographic form. One of my active projects has been the assignment of unattributed types to particular manufacturers and the clarification of their histories through physical and visual research.

Fixing a type’s origins is historically complicated by the widespread pirating of type designs during the mid to late nineteenth century. The pantograph, while fundamental to the mass production of wood type, also made it easy to copy a competitor’s designs by using the type itself as a pattern, subtly modifying the resultant copies to sell as “originals.” While copying created a great proliferation of wood type designs, working through this proliferation creates challenges in fixing a type’s exact origins.

Beyond its substantial holdings of wood type, the Hamilton Wood Type & Printing Museum in Two Rivers, Wisconsin, is a unique repository of the actual machinery used to finish the raw end wood of type blocks; the Museum houses everything from end-grain wood sanders and planers to pantograph patterns and finishing tools. Engaging the actual machinery firsthand to prepare the raw end wood for routing brought to my attention the rough planing patterns on the back of each finished wood type block.

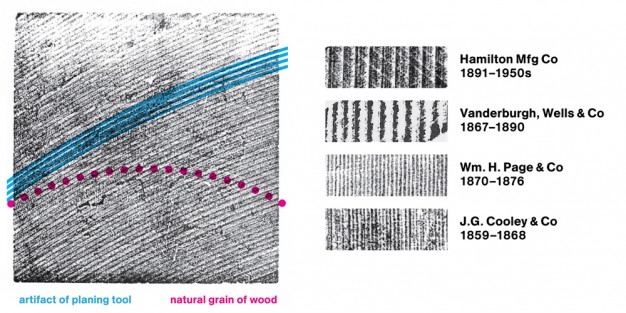

Each manufacturer by necessity created its own machinery for producing type-high wood blocks. The differences in machine construction from manufacturer to manufacturer were made evident in the unique planing patterns that remained on the back of each of their type blocks. These unique patterns seemed most likely a consequence of the variety of finishing machinery utilized by manufacturers.

Each manufacturer by necessity created its own machinery for producing type-high wood blocks. The differences in machine construction from manufacturer to manufacturer were made evident in the unique planing patterns that remained on the back of each of their type blocks. These unique patterns seemed most likely a consequence of the variety of finishing machinery utilized by manufacturers.

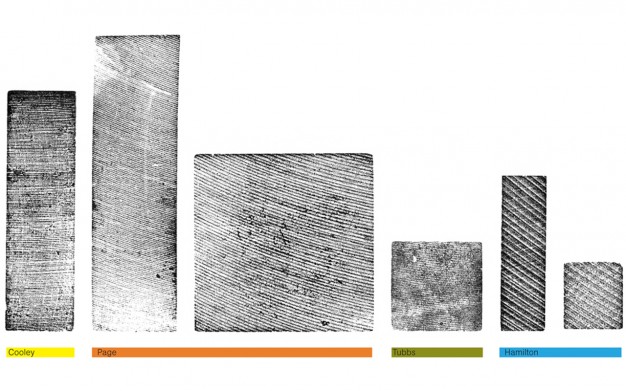

The Kelly Collection, with its range of identified manufacturers, provides an excellent data set for testing this hypothesis. To develop reproducible results, directly comparing the patterns is proving to be the most successful strategy. The patterns on the backs of the blocks from the entire collection have been precisely recorded in print. Scans of these prints have translated the patterns into digital files, which facilitates direct (overlapping) comparison between patterns. The results to date are not yet definitive, but are promising. The findings indicate that there is not one explicit pattern but a set of identifiable patterns that can culminate in indicating a particular manufacturer. This irregularity in patterns from a single manufacturer may be the result of ongoing maintenance to the equipment to keep the finishing blades sharp.

This method of analysis may provide the ability to resolve the identities of type manufacturers for blocks that lack production stamps, since certain manufacturers did not use stamps, and so expand the existing historical description of the Kelly Collection. I intend to develop this particular approach into a generalized method that could be shared with other curators who are attempting to clarify the manufacturer identity of wood types held in other collections, and thus facilitate an historical understanding to type designs not in the Collection.

This method of analysis may provide the ability to resolve the identities of type manufacturers for blocks that lack production stamps, since certain manufacturers did not use stamps, and so expand the existing historical description of the Kelly Collection. I intend to develop this particular approach into a generalized method that could be shared with other curators who are attempting to clarify the manufacturer identity of wood types held in other collections, and thus facilitate an historical understanding to type designs not in the Collection.